2025-10-30 Posted by TideChem view:218

This guide gives hands-on advice for picking PEG linkers in bioconjugation. It provides decision-making tips, things to consider for experiments, and ways to solve common problems. It's not just a general overview; this article points out key design choices, performance pros and cons, and helpful tips for researchers working to get the best PEG conjugates.

In bioconjugation, PEG linkers do more than just connect molecules. They change the physical, chemical, and biological behavior of the final product.

In antibody-drug conjugates (ADCs), PEG linkers keep things stable and allow drugs to be delivered right to tumors.

In protein PEGylation, they make the drug last longer in the body and cause fewer immune reactions, which improves how well they work.

All of this makes PEG linkers necessary for accurate medicine and developing the latest biopharmaceuticals.

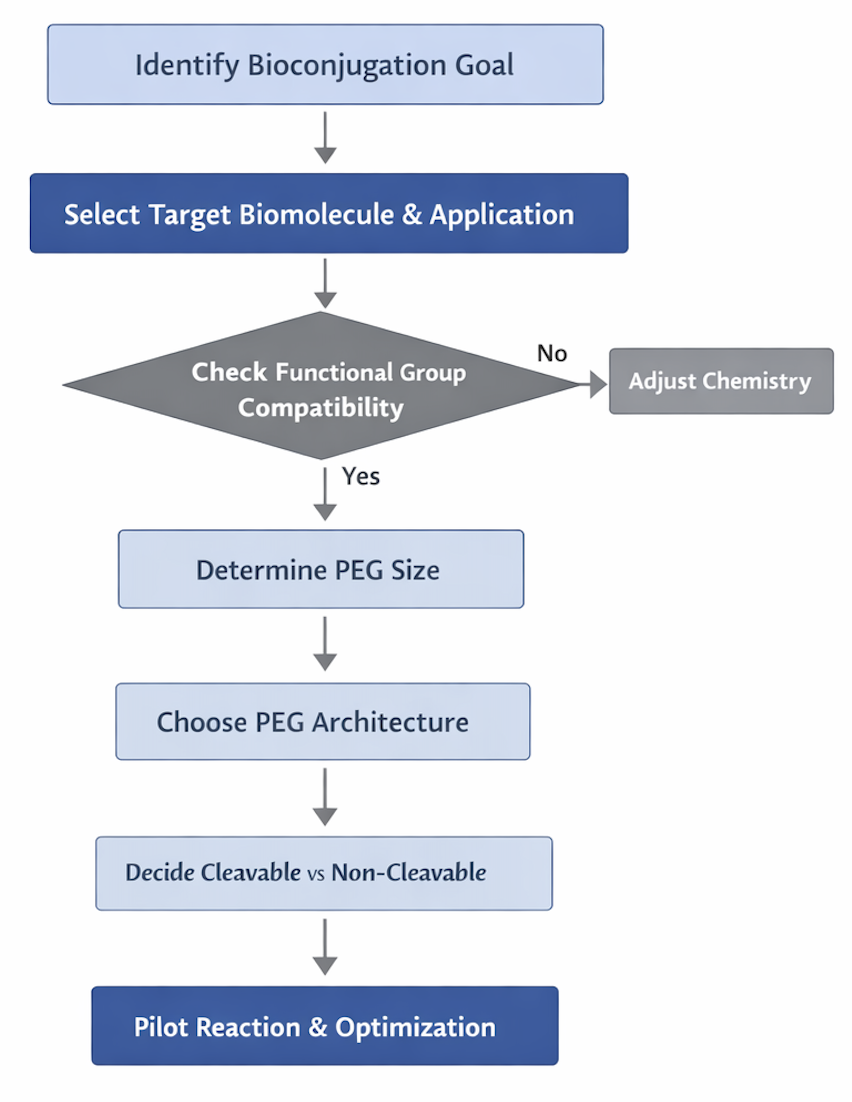

- Step 1: Know what you want to attach the PEG to

- Step 2: Consider which functional groups work well together

- Step 3: Decide on PEG size based on how soluble you need it to be and how much shielding you want

- Step 4: Pick a structure (linear or multi-arm)

- Step 5: Test some reactions and make adjustments

PEG Linker Selection Decision Tree

Linear PEGs, like methoxy PEG (mPEG), heterobifunctional and homobifunctional PEGs, are the most used because they are easy to make and act as expected.

Pros:

Simple to make and purify

Well-understood structure

Great for standard peptide, protein, siRNA, and nanoparticle attachments

Multi-arm PEGs (with 2, 4, 6, or 8 arms) can do more while still being soluble and flexible. They are good for making hydrogels or systems that carry a lot of drugs.

Pros:

Can carry more

Better at crosslinking

Good for assemblies with many functions

Branched PEGs (Y- or U-shaped) offer protection and are more stable against enzymes compared to linear PEGs.

Pros:

More resistant to enzymes

Better shielding

Best for situations where stability is important

The molecular weight of PEG is a key thing that changes solubility, how long it stays in the body, and shielding abilities.

For small molecules, peptides, and siRNA attachments: use PEG ≥ 5 kDa for good shielding and flexibility.

For protein PEGylation: often use lower molecular weights (≤ 5 kDa) to keep a balance between activity and how the drug moves through the body.

A tip for setting up experiments:

When you are trying to find the best linker length, try a few different sizes (2 kDa, 5 kDa, 10 kDa) to see how they change solubility, bioactivity, and clearance.

The linker structure—linear, branched, or multi-arm—decides how many functional groups can be attached and how the molecule acts in water.

Also, think about:

Bonds that can be broken (like disulfide, hydrazone) for on-demand release;

Targeting groups (like folate, peptides) for delivering to specific places;

Spacer flexibility to avoid getting in the way of big biomolecules.

PEG linkers usually have groups like NHS esters, maleimides, amines, azides, or thiols. Picking the right one makes sure the attachment happens in the right spot and gives a high yield.

Tips:

Amine-reactive PEGs (like NHS-PEG) are good for proteins or peptides with lysine.

Thiol-reactive PEGs (like maleimide-PEG) are better for targets with cysteine.

Click-reactive PEGs (azide or alkyne) are great for bioconjugation that does not affect other parts.

Tip: When working with big proteins, always check PEGylation before making large amounts using SDS-PAGE or MALDI-TOF.

PEG linkers should be chemically stable, resistant to enzymes, and not cause immune reactions.

For medical uses, pick medical-grade PEGs (GMP or USP standard) to be safe and consistent.

Check:

How stable it is in water

How stable it is in serum at 37 °C

If it has any endotoxins or impurities

| Selection Factor | Key Question | Recommended Approach |

| Functional Group | Which reactive group matches your biomolecule? | Choose NHS for amines, maleimide for thiols, click handles as needed |

| Molecular Weight | Do you need long circulation? | ≥5 kDa for proteins, balance solubility vs steric hindrance |

| Architecture | One payload vs multiple payloads | Use linear for single, multi‑arm for high loading |

| Cleavability | Do you need triggered release? | Pick enzyme/acid cleavable linkers |

Decision Matrix Table

PEG linkers keep the drug stable and help control its release in target tissues. The right linker design improves how well the drug works and lowers side effects.

PEGylation is still the best way to improve how proteins move through the body. It makes them last longer, reduces kidney clearance, and makes them more stable—used a lot in cytokines, enzymes, and peptide hormones.

Lipids or polymers with PEG make nanoparticles less likely to be detected, making them last longer and improving where they go in the body—important for mRNA and RNAi treatments.

Start with small tests to find the best PEG length and chemistry.

Use different attachment methods to keep the biomolecule active.

For ADC or peptide attachment, keep the linker-to-payload ratios the same across batches.

For hydrogels or carriers, pick multi-arm PEGs for stronger crosslinking and mechanical strength.

Check stability and bioactivity in realistic conditions before testing in animals.

For basic info on PEG linker structures and uses, see What Are PEG Linkers?. For a guide on how to pick, refer to How to Choose the Best PEG Linker for Bioconjugation.

Picking the right PEG linker is key for making good bioconjugates. Things like molecular weight, structure, functional group compatibility, and stability affect how well the conjugate works and how safe it is.

By using a smart design approach, researchers can make PEG conjugates with great pharmacokinetics and functionality, which helps move forward medicine, diagnostics, and new treatments.